In the previous blog post Skybuffer experts show wireframes development process for SAPUI5 (OPENUI5) terminal application implementation. Let’s keep the same scenario that Warehouse forklift is broken and Loader Operator creates Malfunction Report to get a remote technician assistance. And let’s try to see how many steps in standard SAP ECC system you have to run to get the same outcome as of the SAPUI5 terminal application. That will help to assess how SAPUI5 (OPENUI5) transactions implementations facilitate day-to-day activities at enterprise environment.

STEP #1 :: Setup User Default Data

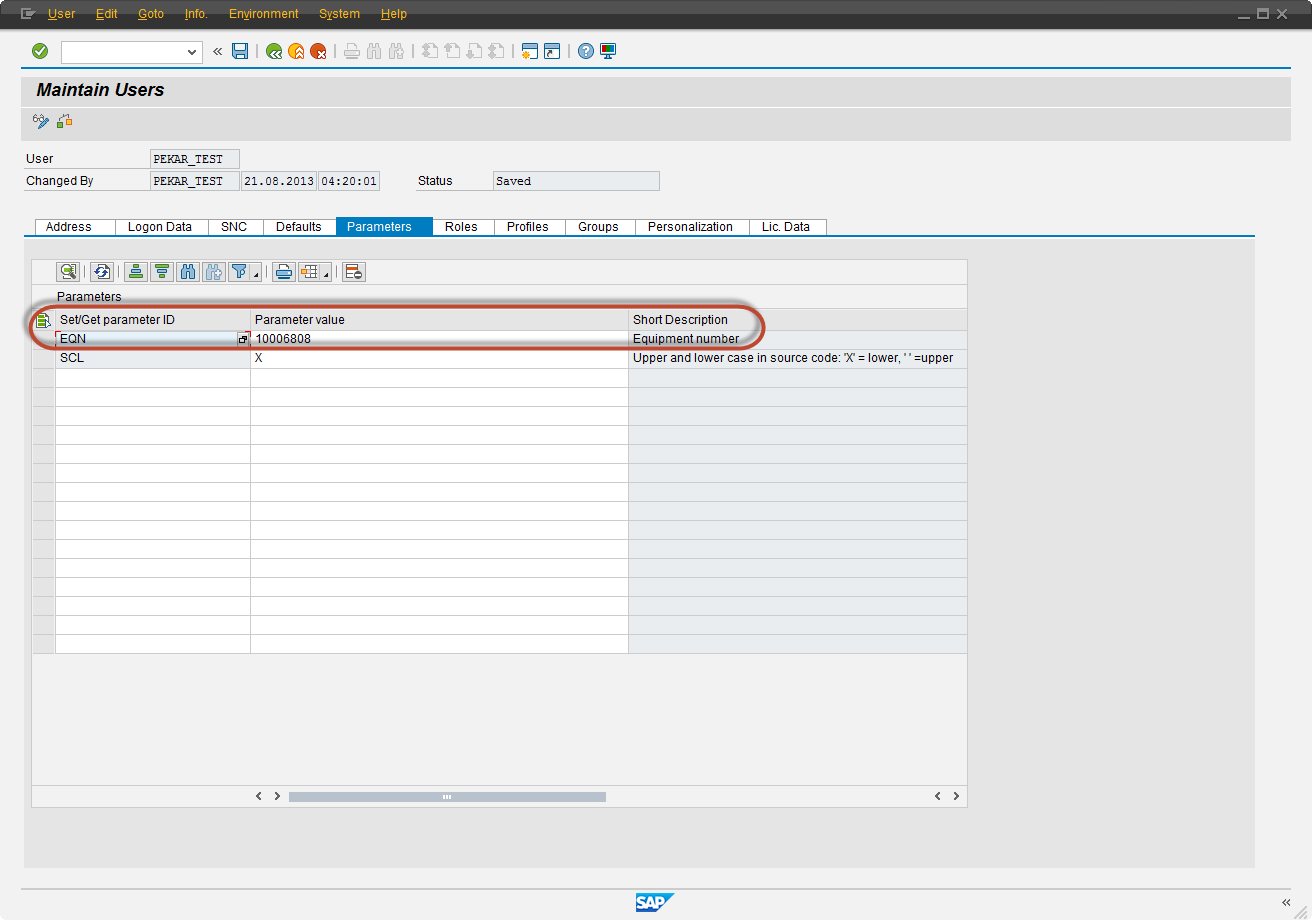

Each employee in his/her shift is using a certain forklift that could be assigned to his/her user ID in SAP system.

In this SAP ECC scenario we assume that equipment is assigned to the user master record via EQN parameter using SAP transaction SU01.

STEP #2 :: Create M2 Notification

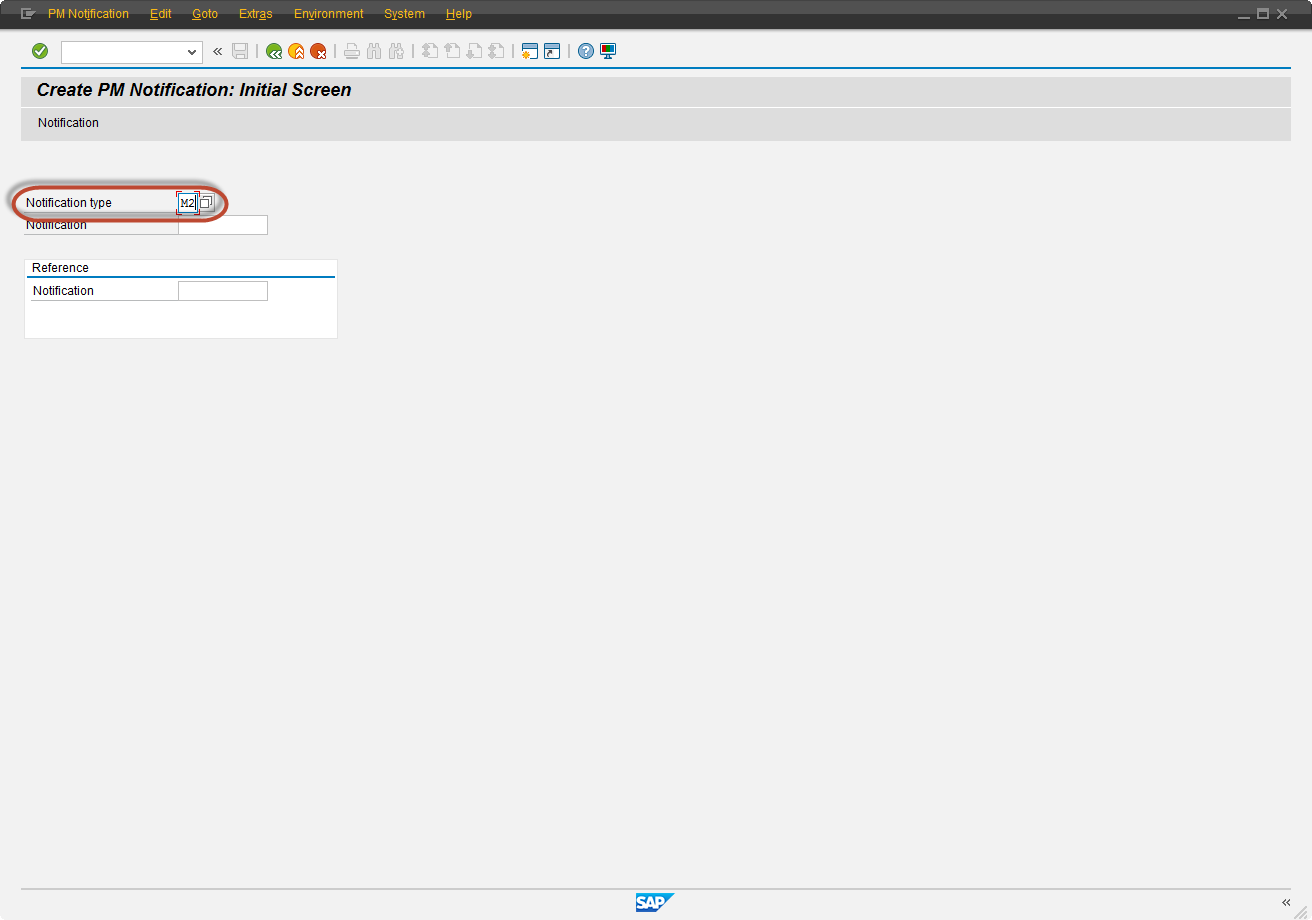

In case of breakdown of equipment warehouse employee has to report this using SAP PM Notification of M2 type.

In standard SAP solution user interface it could be done via IW21 transaction:

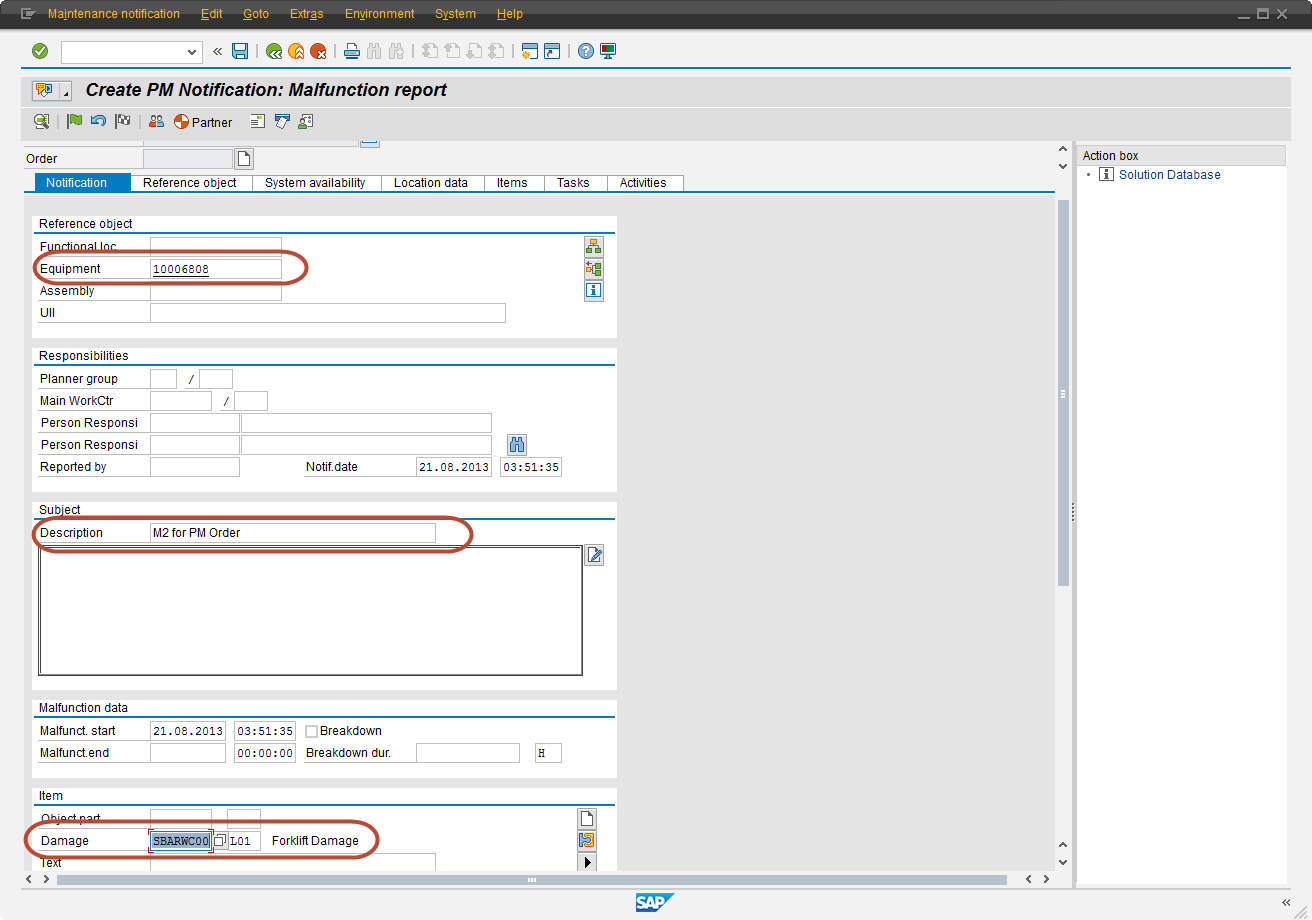

Plant Maintenance notification in SAP GUI is much more powerful object that is required for our scenario. That is the reason why malfunction report could not be created from one screen (like it is in SAPUI5 transaction case).

On the second step in IW21 transaction user needs to hit ENTER button and provide an equipment number from the step #1. The highlighted data fields should be filled:

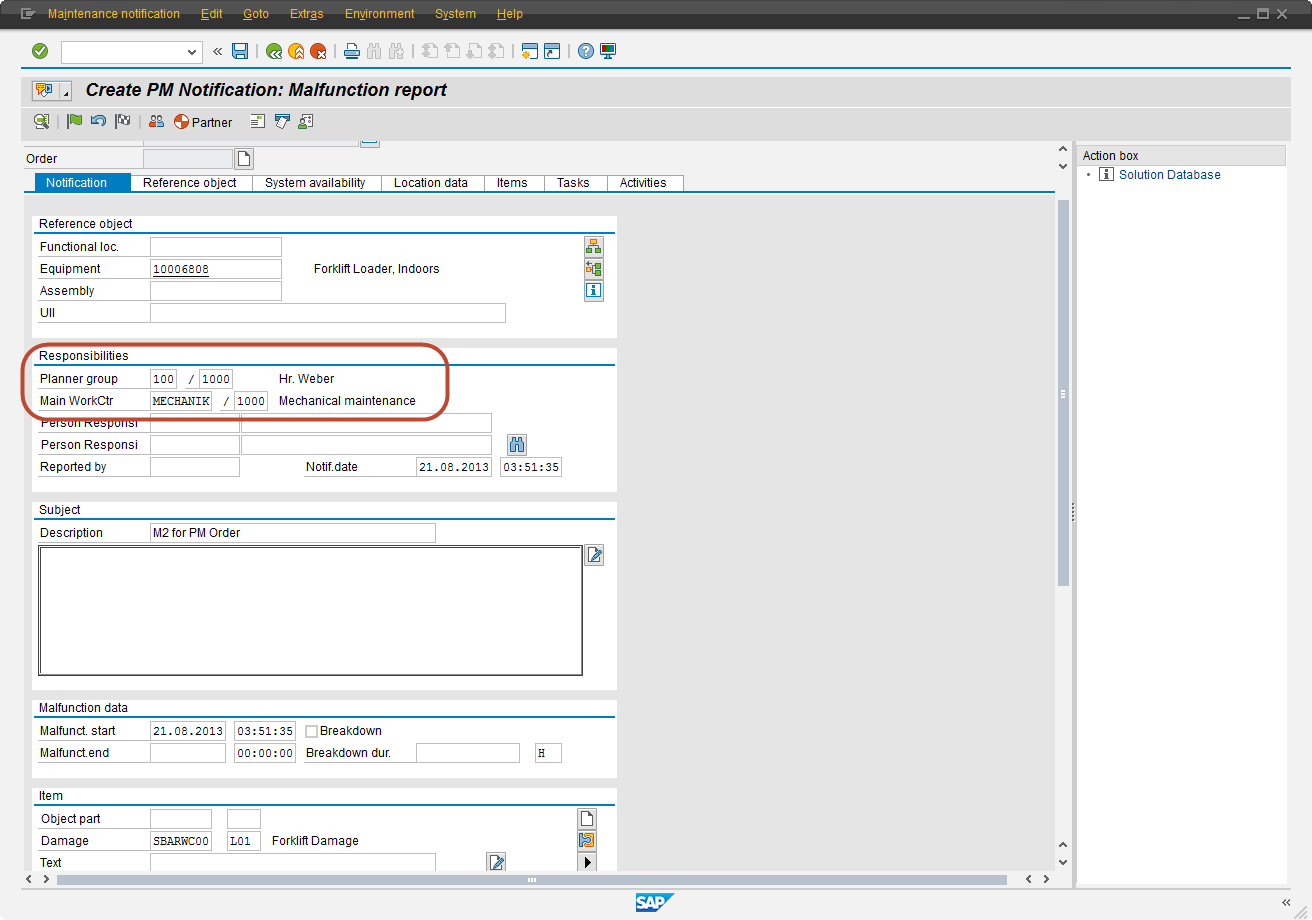

User hits ENTER and finds out that Responsibilities section data is inherited from the equipment master record:

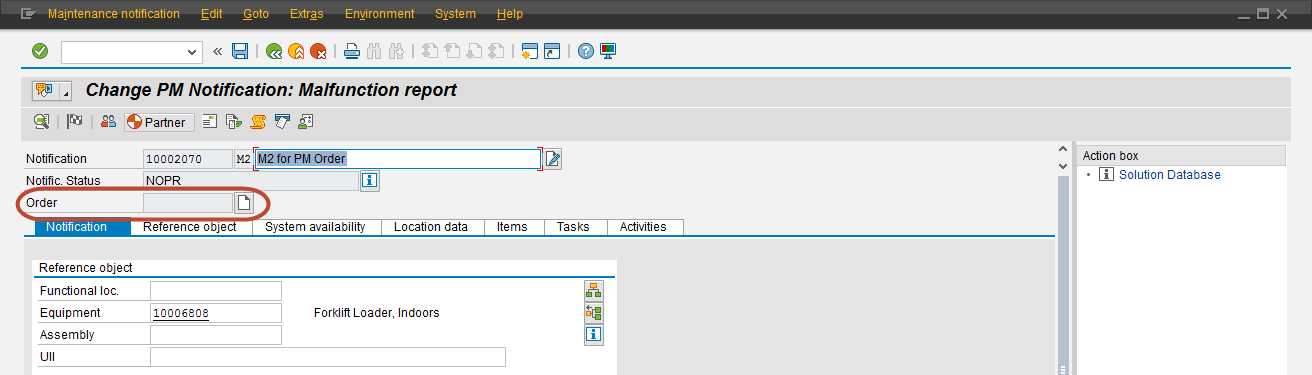

As the last step, user should put notification in process and save it. Notification number will be displayed at the screen bottom:

RESULTS: breakdown report is created and registered in the plant maintenance tickets queue. Technician will pick it up and put in process as soon as he/she is available.

STEP #3 :: Technician (Responsible Work Center) is Monitoring Notifications List and Creates PM Order

Remote technician of the work center responsible is monitoring the list of M2 notifications without Plant Maintenance Order assignment (newly created). He/She takes the next one from the queue and creates PM Order.

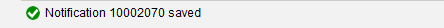

List of M2 notifications could be seen in SAP via transaction IW28 with the following parameters:

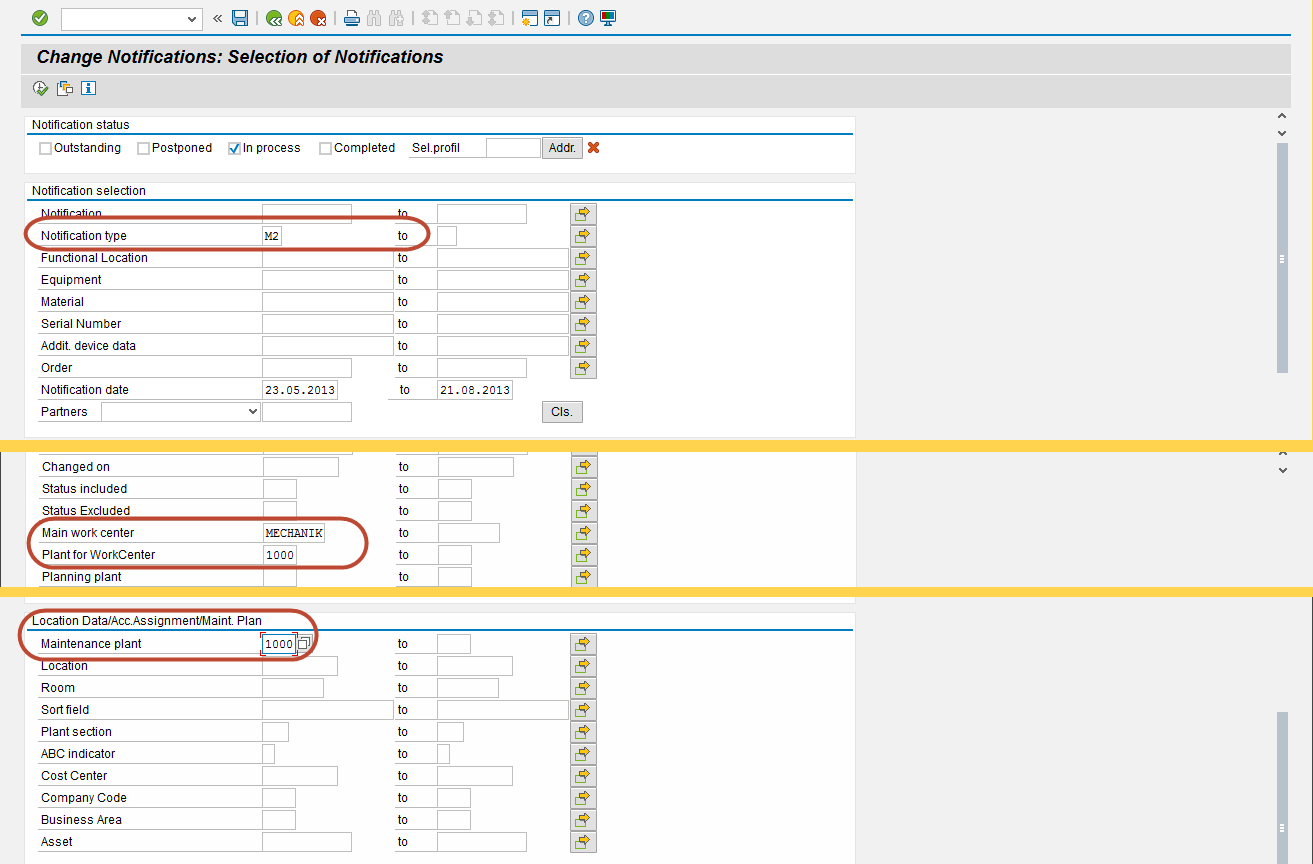

When Execute button is clicked, the list of M2 notifications is shown based on the filtering settings:

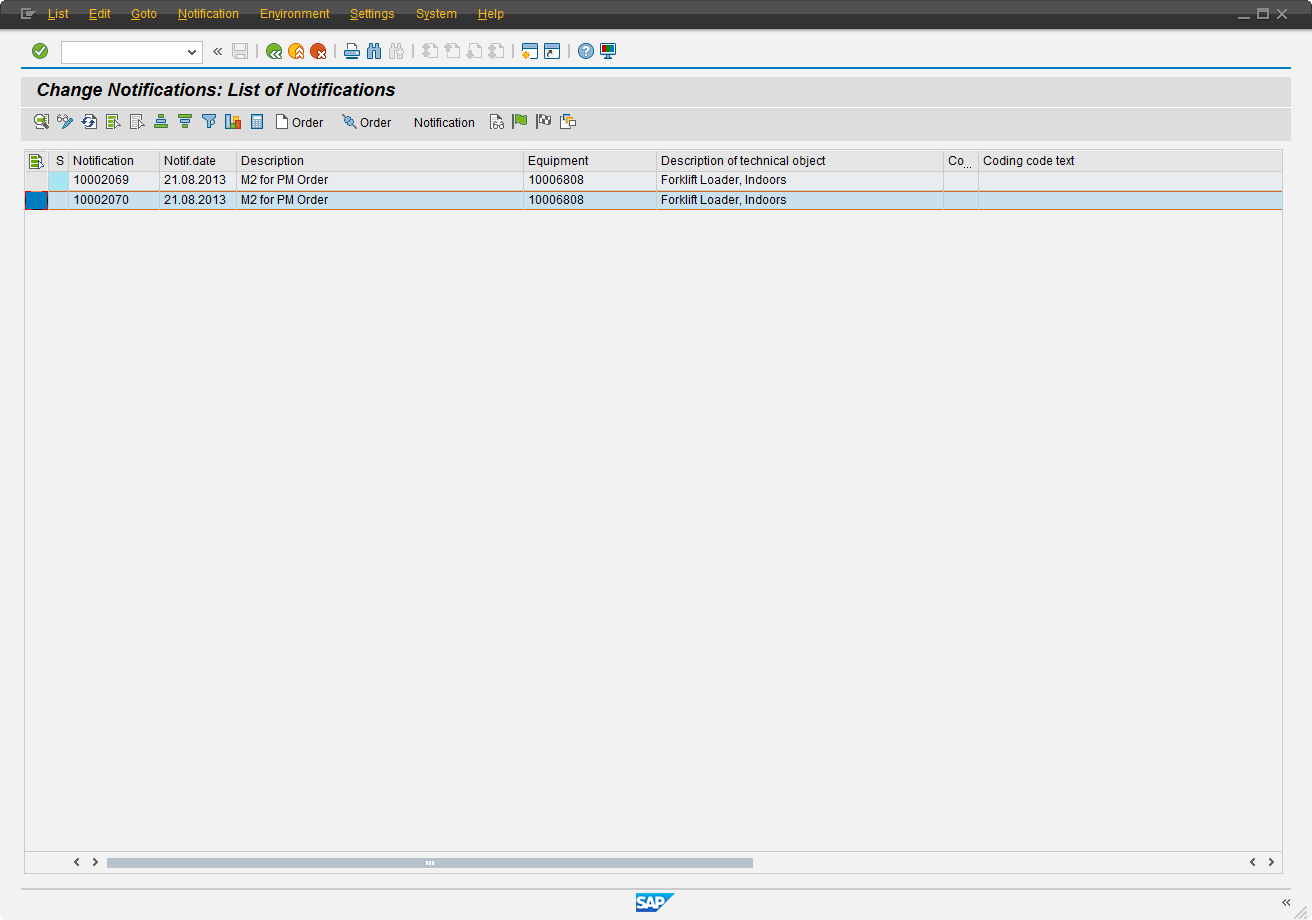

Technician can see that there are two notifications are in his/her queue. He/She double clicks on the certain one and creates a PM Order:

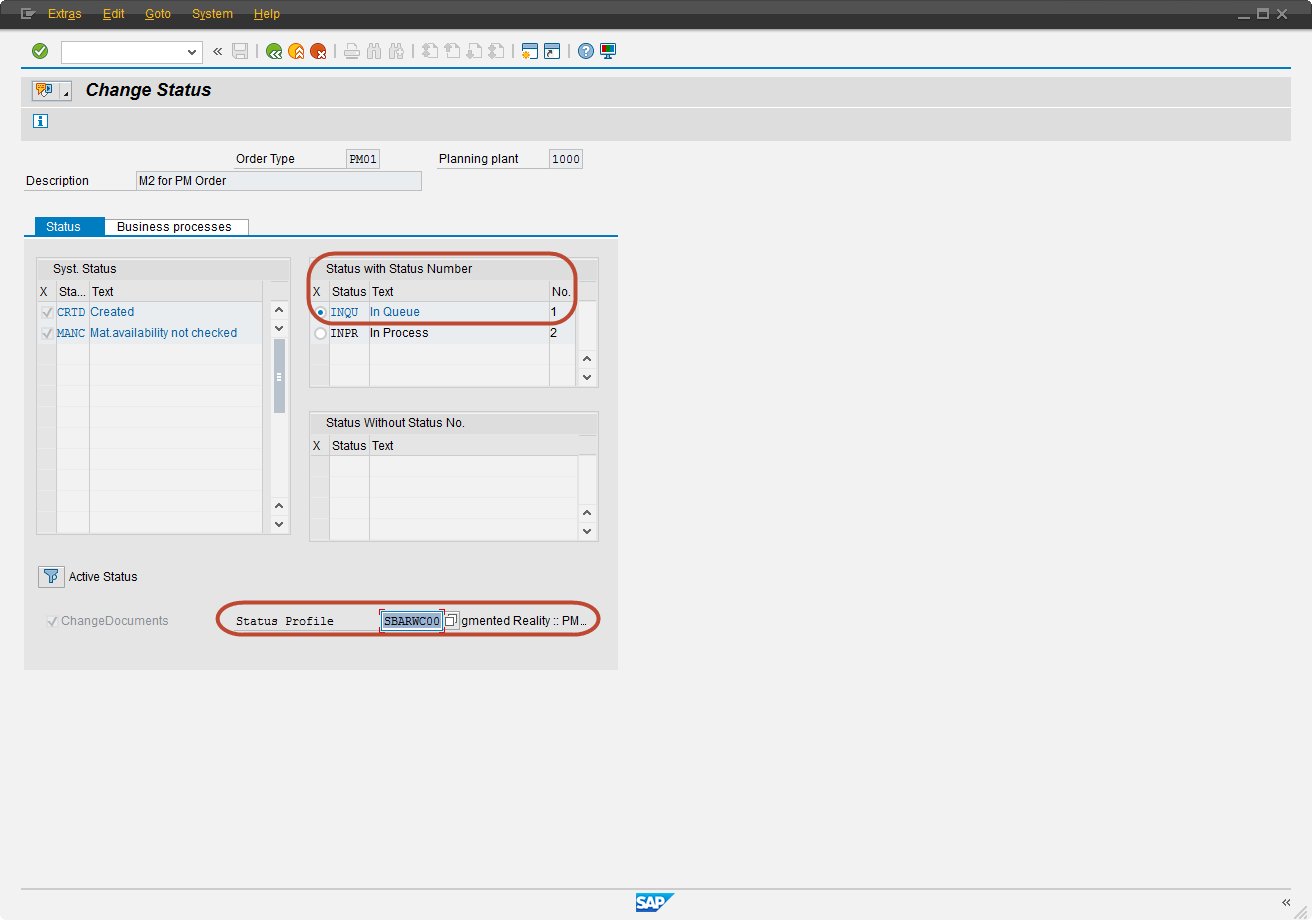

When PM Order is created, user status is set to INQU (In Queue).

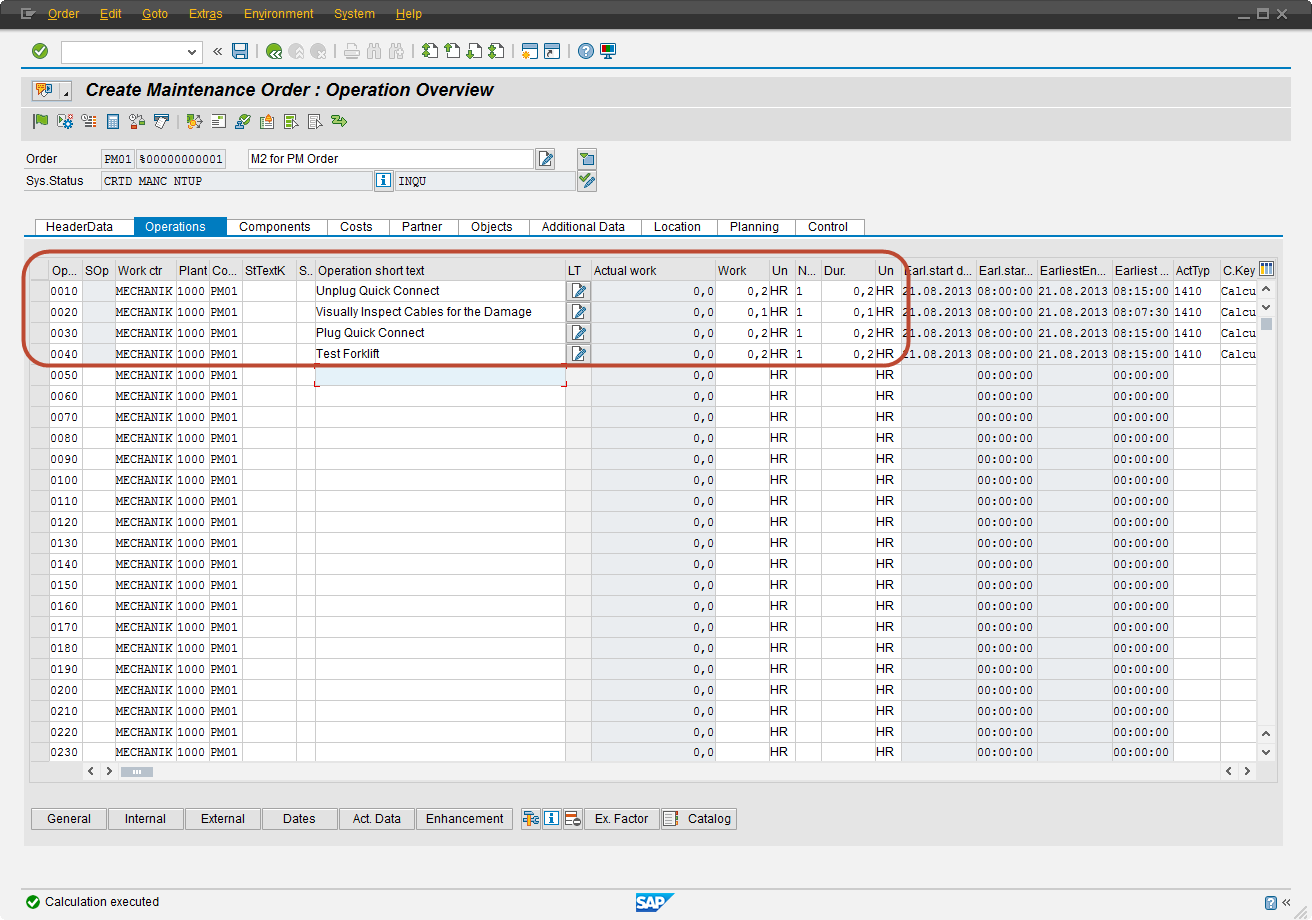

Technician is video chatting with Operator and then updates the Plant Maintenance Order with the operations list to be executed:

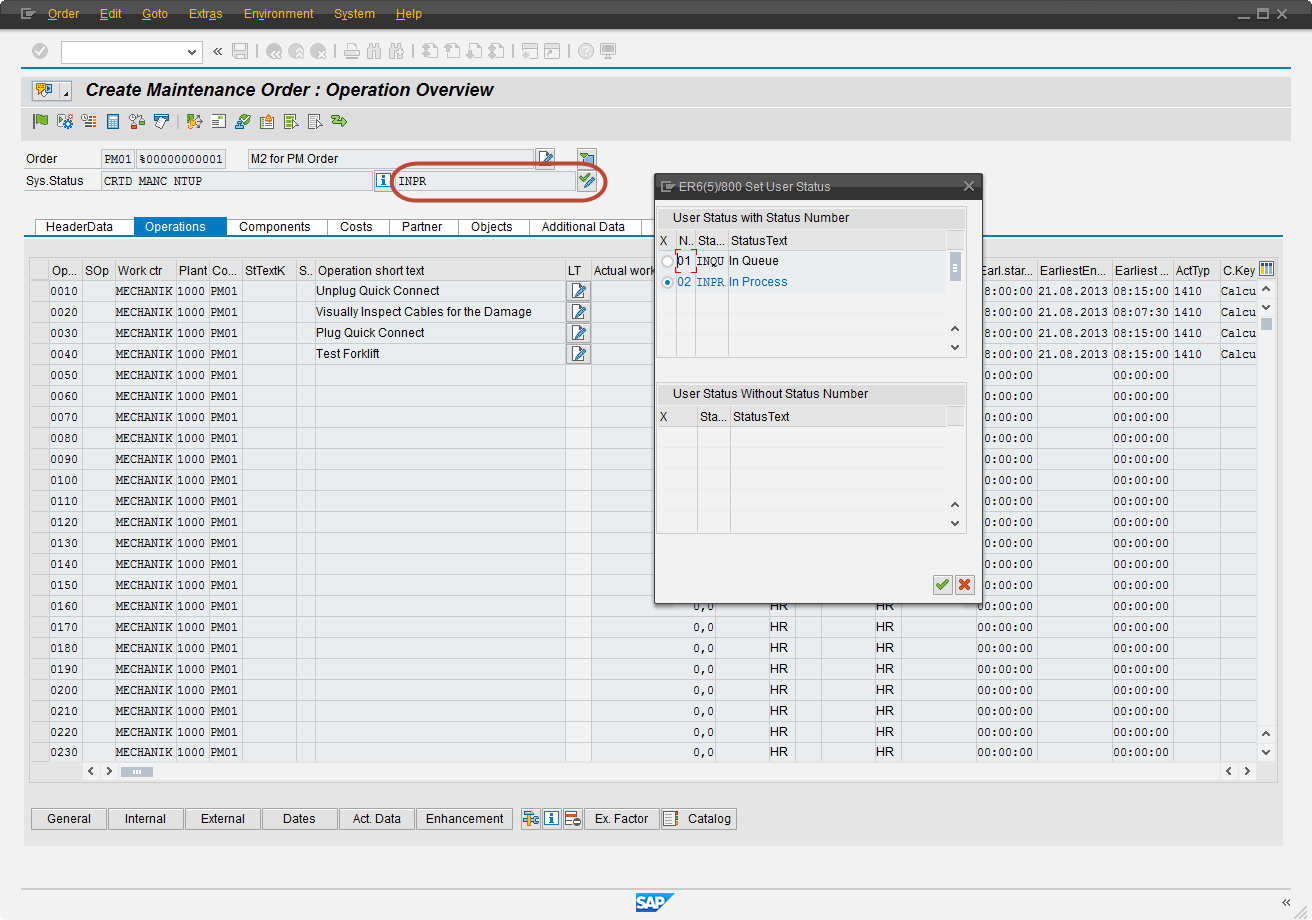

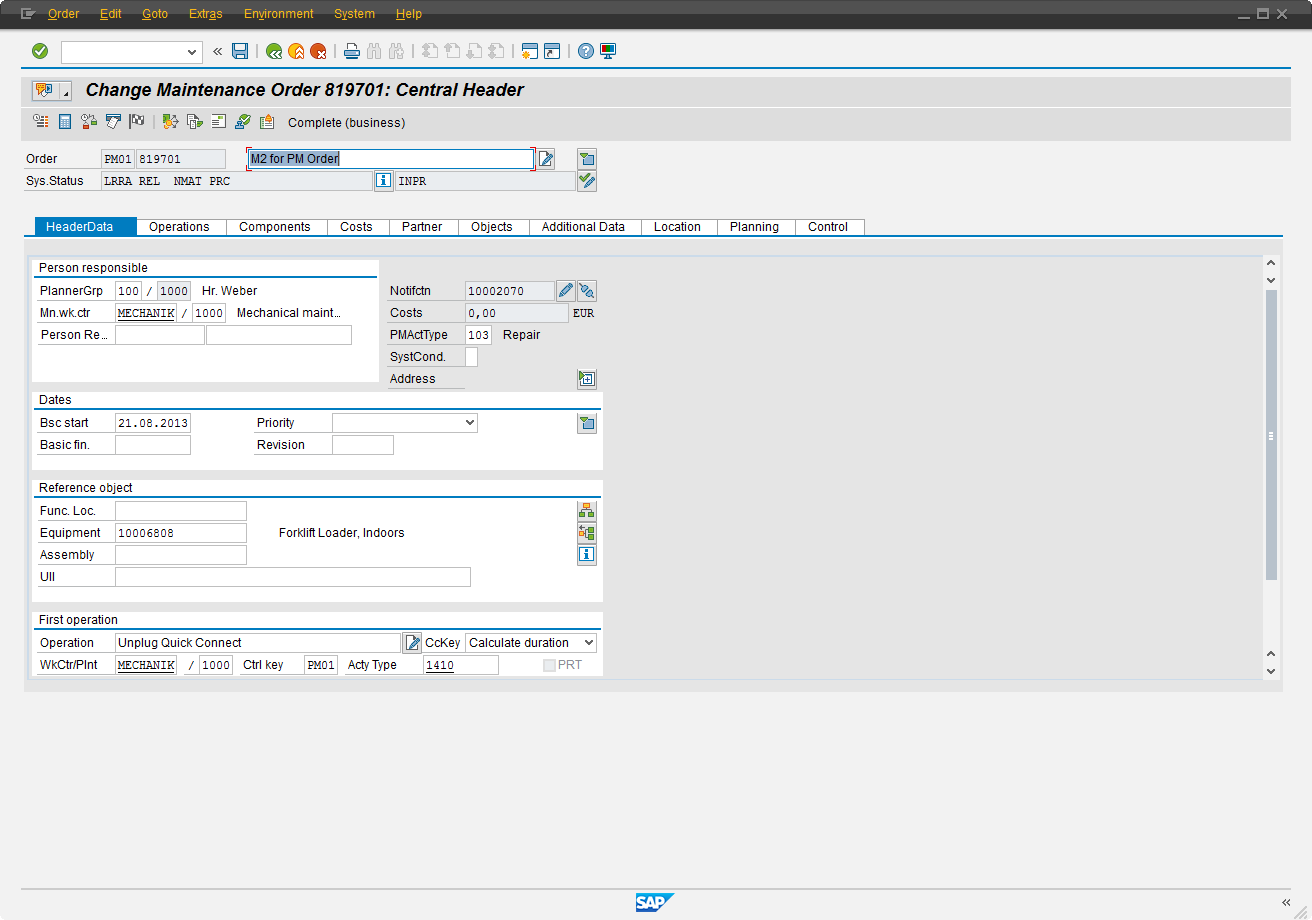

Technician explains operations to Operator and change PM Order user status to INPR (In Process):

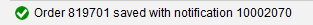

Technician Releases and Saves the Plant Maintenance Order::

RESULT: notification is not in the queue, PM Order with operations is created and Operator is supposed to fix the forklift. Operator can call back again, in this case user status will be set back to INQU and Technician will serve the maintenance request from the queue.

STEP #4 :: Operator Has Fixed the Forklift and Completes the Maintenance Order

When all operations have been carried out, Operator can verify that forklift is fixed. He/She clicks COMPLETED button at the terminal, in case SAPUI5 custom transaction is developed and used.

In SAP GUI (standard SAP way) it is possible to use transaction IW32 and open the Maintenance Order:

Technical Completion button should be clicked and then Plant Maintenance Order should be saved.

RESULTS: via this step execution the confirmation of the damage repair is posted at SAP ECC system.

Conclusion

It is possible to implement in warehouse self-maintenance scenario using only SAP standard transactions, but in this case it is not possible to make it as a one screen terminal solution.

To facilitate in warehouse self-maintenance process and to implement it as a terminal application, Skybuffer experts in SAP UI Development decided to build a prototype of the solution using SAPUI5 (OPENUI5) Framework and SAP.M (Firoi like) widgets.

You can get inside the mockups (wireframes) development in our blog post:

SAP OPENUI5 (SAPUI5) – In Warehouse Self-Maintenance – Mockups Development

Skybuffer SAPUI5 Applications Port

Please feel free to execute and test SAPUI5 implementation of the business process online!