Maintenance work activities costs reduction could be achieved not only by the decrease of the scope of work but also by the optimization of the technician performance. Oil Well Maintenance solution from Skybuffer allows maintenance work to be done faster, cheaper and with better quality.

Business Case

Maintenance work for the several oil wells is performed by one technician or a maintenance crew that is driving the truck among the oil field from one well to another.

Spare parts are taken by technician at the beginning of the shift and stored in the truck boot.

The software should help technician to find out the best route based on the spare parts, tools that are in the truck and maintenance work activities that are scheduled to be performed for the date.

Oil Well Maintenance Application

SAPUI5 application could be executed from Skybuffer application port:

Skybuffer :: Oil Well Maintenance

Oil Well Maintenance User Guide

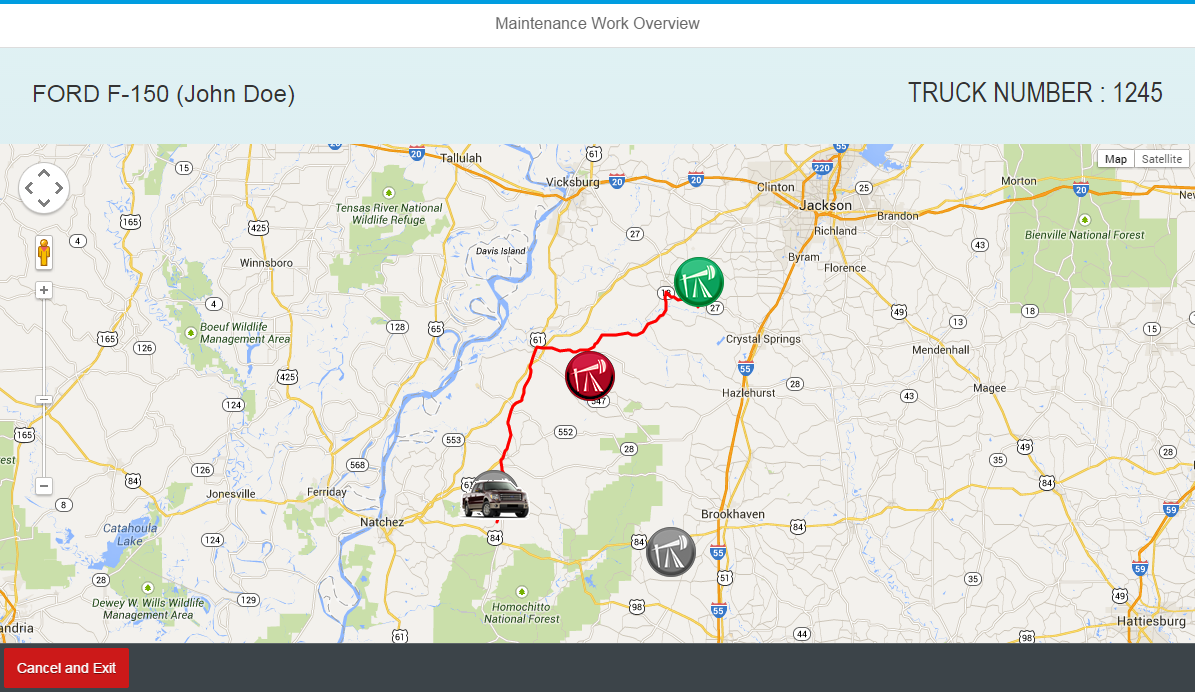

A map based web application could be executed on the technician mobile device (like, for instance, tablet PC) and displays information filtered by the truck number that is used by him.

The Login Screen

On the login screen the truck number should be entered. It is not necessary to use the number plate because the special numbering system could be used to assign the technician to the truck stock.

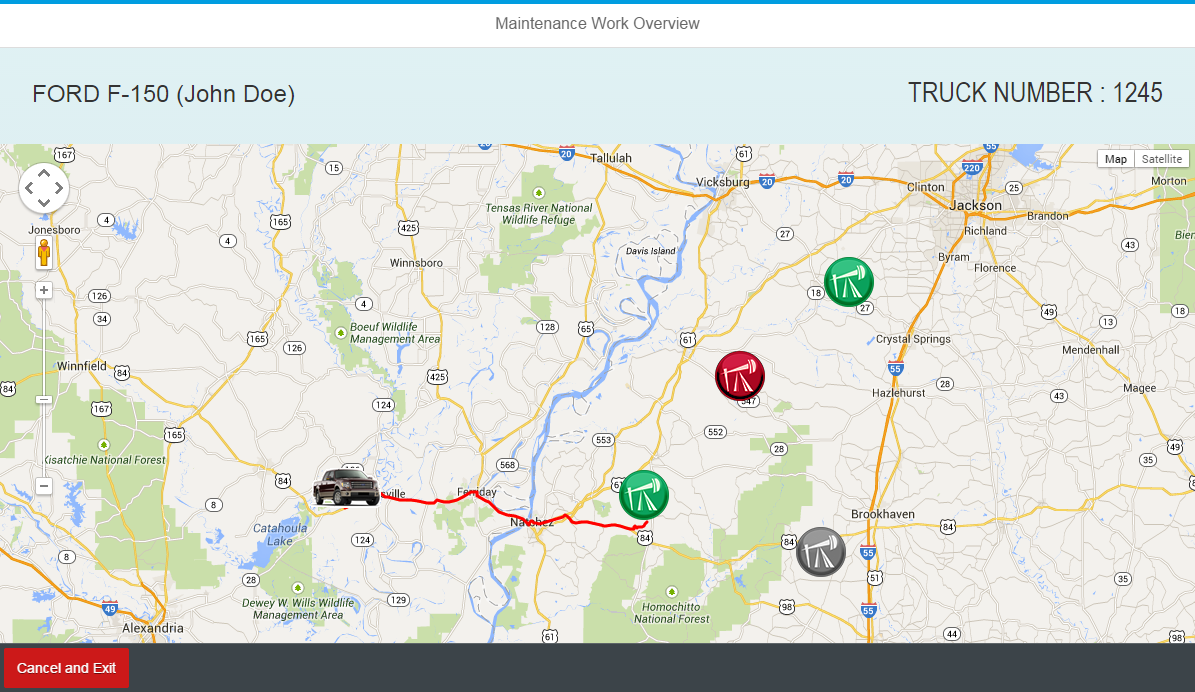

The Main Screen

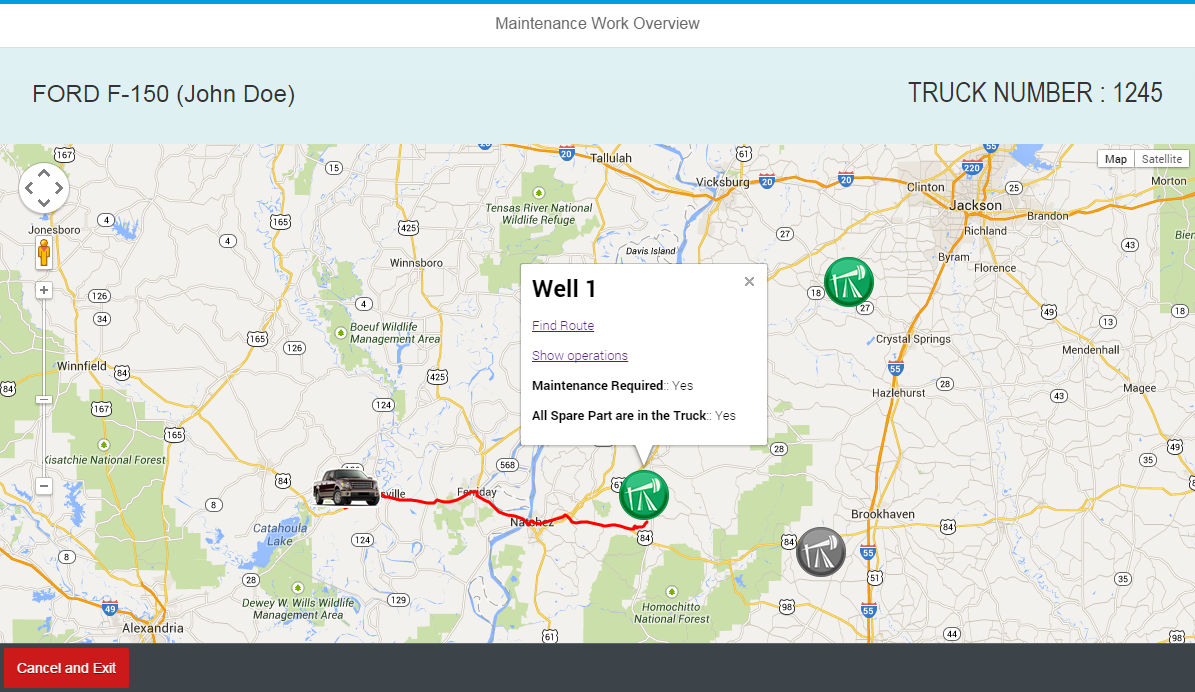

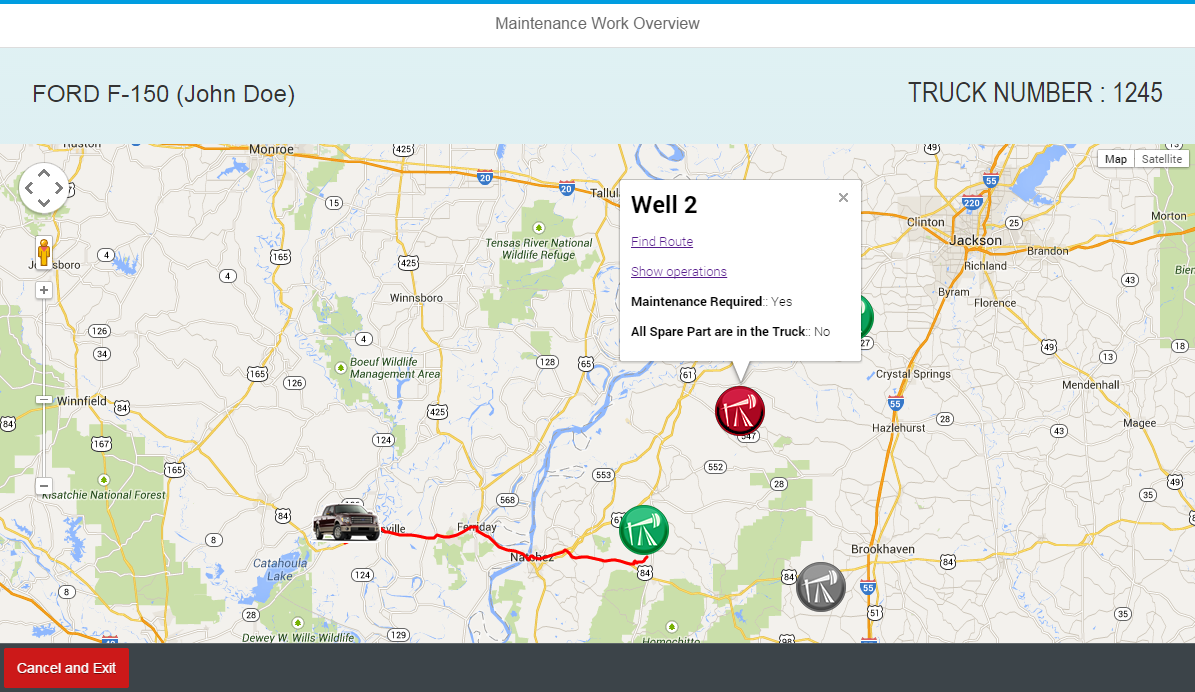

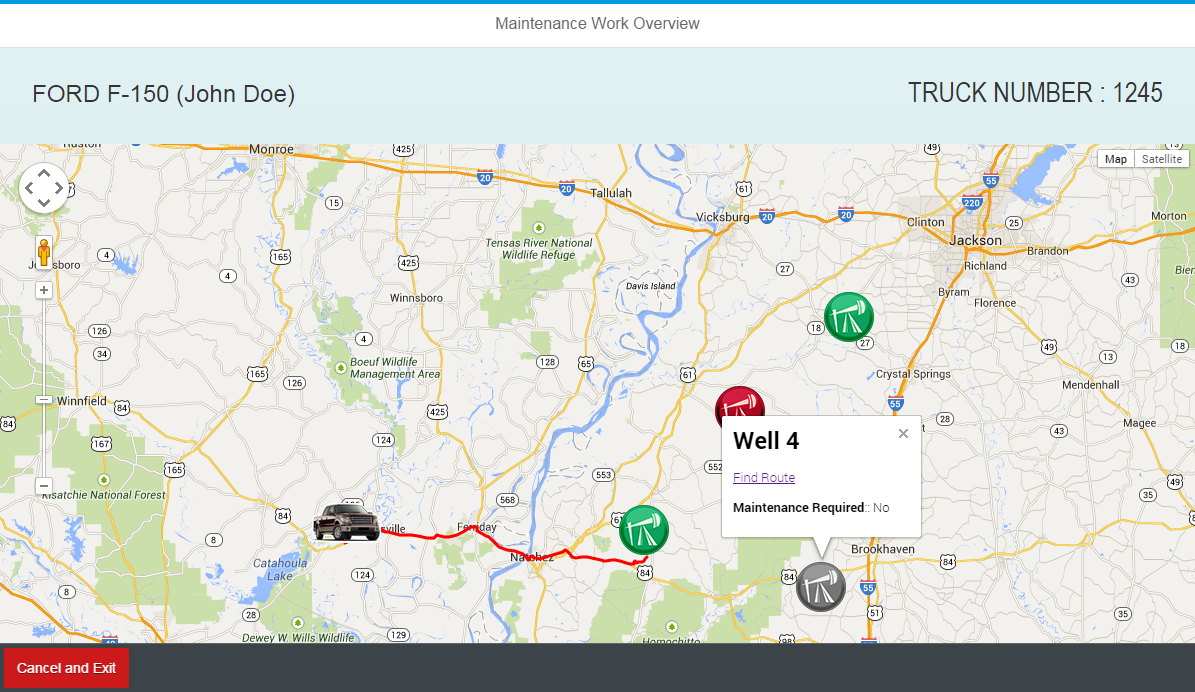

On the main screen it is possible to see the current location of the truck and the work that is scheduled for the technician.

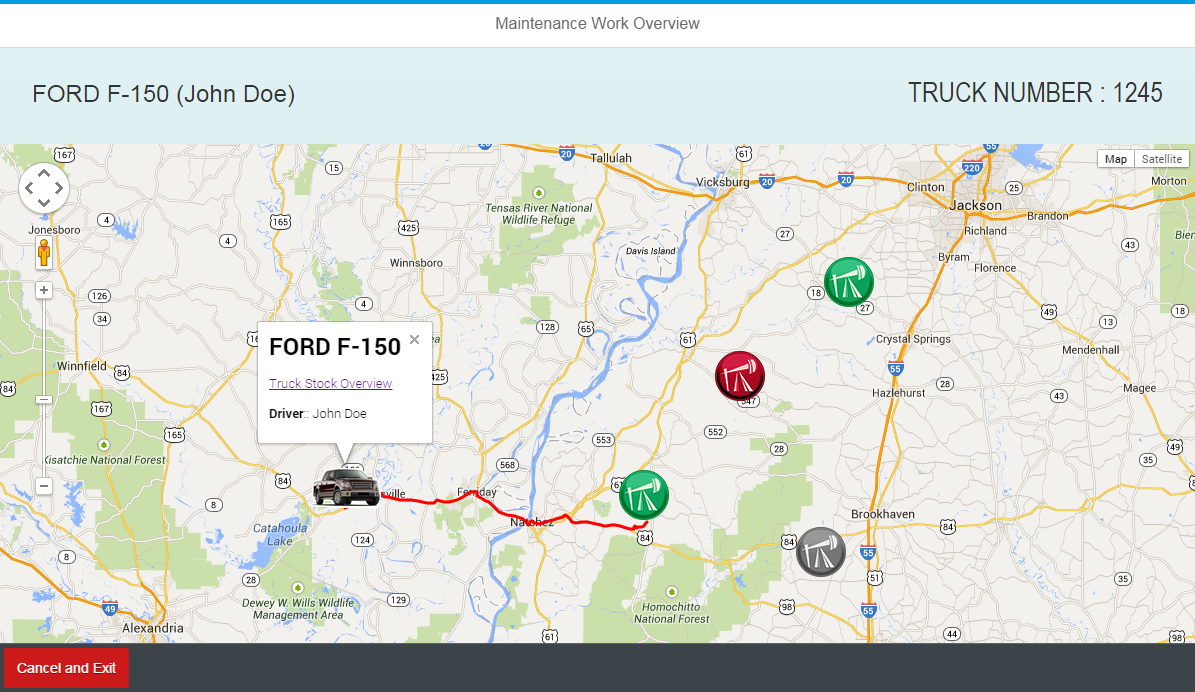

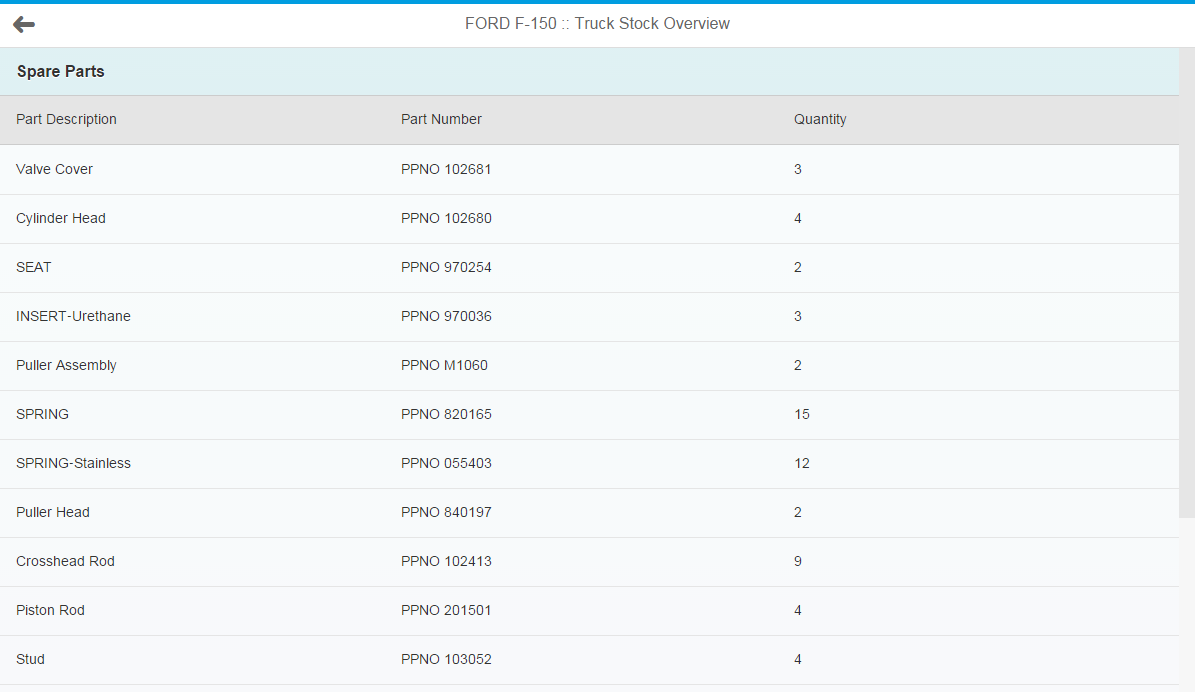

The Truck Stock

The truck information could be displayed by the simple click on the truck image.

There is a link for the truck stock overview is available. When it is clicked a new screen with the spare parts list that are stored in the truck is shown:

Oil Well scheduled maintenance summary could be seen by clicking on the well image. Green color is used to highlight oil wells that could be served by the technician:

If not all spare parts that are needed for the certain oil well maintenance are in the truck stock, then the oil well is highlighted with a red color:

If there is no maintenance work planned for the oil well, then this well will be greyed out:

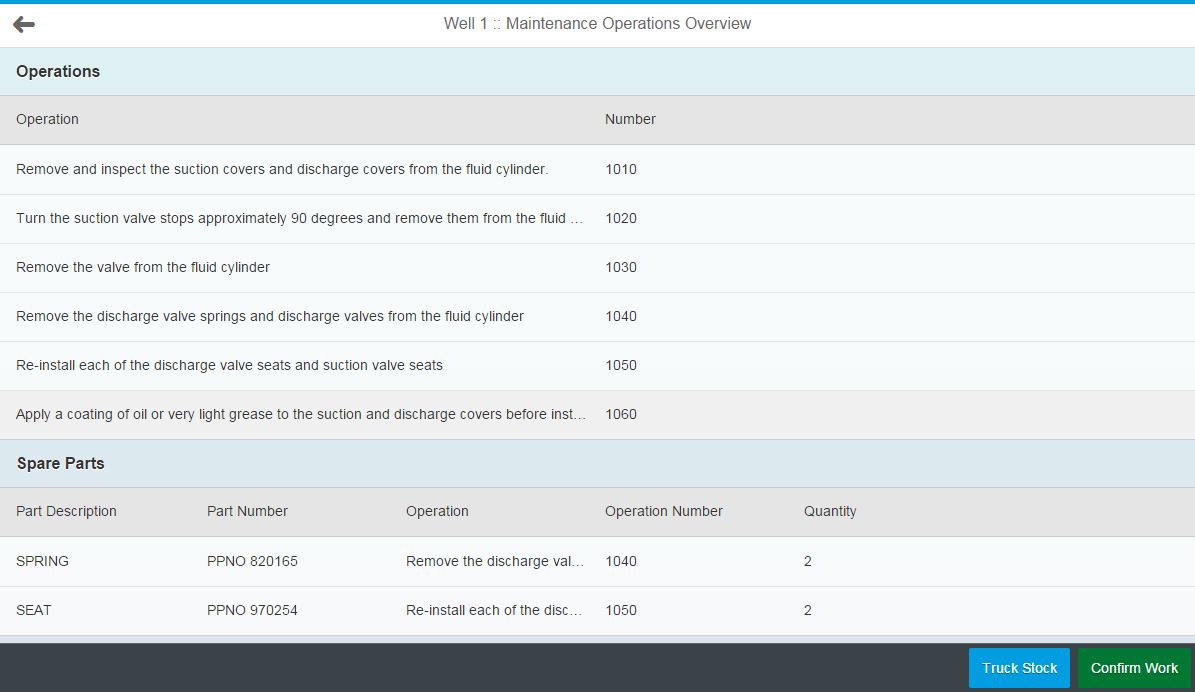

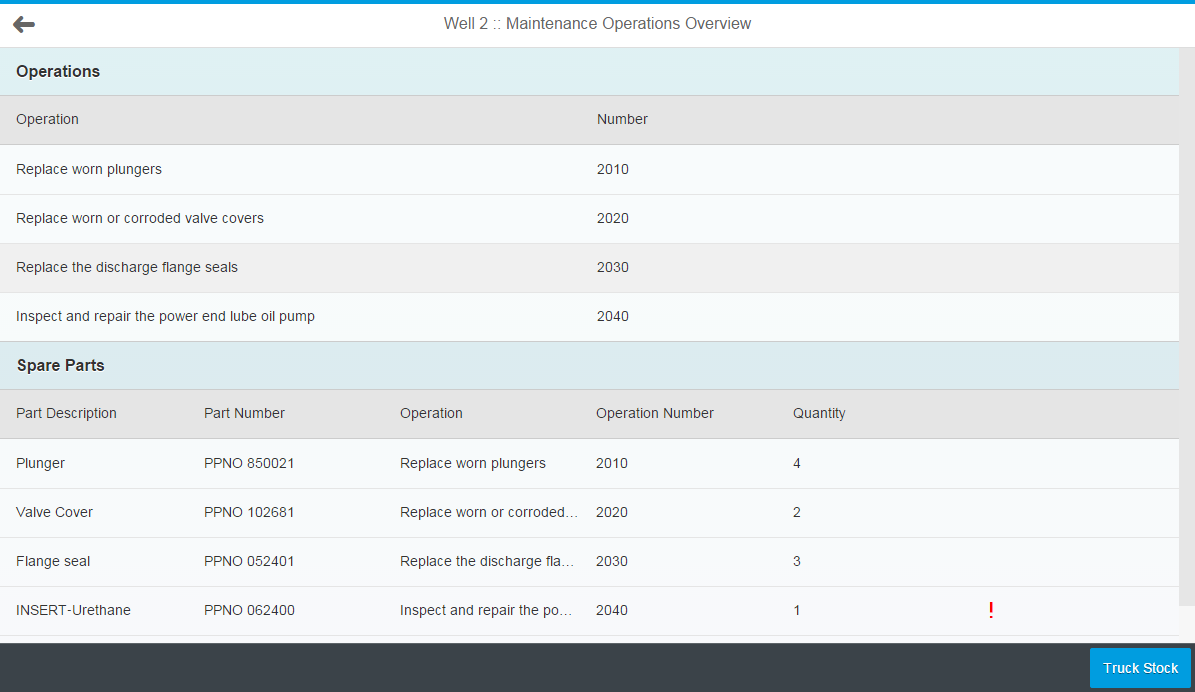

Maintenance Operations and Spare Parts List

For all “green” and “red” oil wells it is possible to see the maintenance operations and spare parts list:

If “red” oil well is selected then system will highlight spare parts that are not in the truck stock:

Work Confirmation

Technician could confirm an operations that are executed and spare parts that are consumed. Depends from the requirements it is either possible to adjust the spare parts list, or spare parts quantities, or operations that are done, or number of hours that is spent for maintenance activities execution.

In this application technician can confirm spare parts consumption and work that is done by clicking on the green Confirm Workbutton. Because in simulation mode GPS coordinates of the truck are not available, application will shift the truck to the oil well for which work order is confirmed:

System has calculated the optimal route for the next maintenance to be performed by the technician.

Results

SAPUI5 application for Oil Well Maintenance helps to:

- Calculate an optimal maintenance truck route that saves technician working hours and fuel

- Exclude oil wells that could not be served because of the spare part lack in the truck stock

- Get an overview of work to be done

- Get an updated information of the breakdown maintenance orders